The term "biomass pyrolysis" refers to the thermochemical conversion of biomass into low-molecular substances such as charcoal, liquid, and gas. This transformation takes place during the biomass pyrolysis machine process. This procedure needs to be carried out in an environment in which the supply of air is either severely constrained to a small volume or completely eliminated altogether. The technology of biomass pyrolysis machine can convert low-energy-density biomass that is difficult to handle using conventional methods into high-energy-density gas, liquid, and solid products at a low cost and in a production process that is continuous, thereby reducing the volume of biomass and making it easier to store and transport. This can be accomplished in a production process that is continuous. This is something that can be achieved through the use of a production method that is continuous. In addition to this, it is able to extract chemicals from bio-oil that have a high value addition to them. These chemicals can then be used in other processes.

A comprehensive analysis of the features that can be found on a biomass pyrolysis machine that operates continuously

The traditional method of producing carbon cannot achieve continuous carbonization, which ultimately leads to low levels of e. Because the traditional method of making carbon cannot achieve continuous pyrolysis machine carbonization, the economic benefits are significantly reduced. In addition, the carbonization process will produce a significant amount of smoke and dust, leading to air pollution. This is contrary to the national environmental protection policy, which seeks to preserve the natural environment.

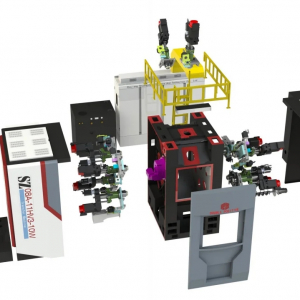

Recent developments at our company have resulted in the creation of a device that is capable of carrying out continuous on biomass. There are two distinct layers that make up the structure of the main drum. The cylinder's body is made of stainless steel, which is not only resistant to high temperatures but also to corrosion. This makes stainless steel an ideal material for the construction of the cylinder. At the same time, a new method of indirect heating is implemented in order to improve the thermal efficiency of the equipment and extend the amount of time that it can be used before it must be replaced. This was done in order to improve the overall quality of the product. This was done so that the equipment could be used for a longer period of time before it needed to be replaced, and this was accomplished by doing what was just described.

The continuous biomass machine is a fantastic illustration of how a single piece of equipment can serve a variety of functions. This piece of equipment can be used to pyrolyze and carbonize biomass, which includes things like sawdust, coconut shell, bamboo chips, straw, and other materials of a similar nature. In addition, it can be put to use in the process of carbonization to treat sludge, household waste, electronic waste, and other materials of a similar nature. A device known as a continuous biomass pyrolysis machine has the capability of pyrolyzing and carbonizing a wide variety of biomass, including sawdust, coconut shells, bamboo chips, straw, and other types of biomass. At no point in the process does any smoke or other form of pollution emerge as a direct result of the operations that are being carried out.

The fundamental processes that are taking place inside of a biomass pyrolysis machine that is always running

Continuous carbonization machine main structure

Before the material can be fed into the crushing and drying equipment, it must first fulfill all of the requirements that are listed in the following paragraphs:Both the moisture content of the material and its size must be less than 30 millimeters, and the moisture content must be less than 15%.

Pyrolysis and discharge – the main body of the biomass pyrolysis machine is formed by nesting inner and outer cylinders, and the main combustion of the outermost layer is treated with ceramic fiber flame retardant cotton for heat preservation; when the machine is operating, the materials that meet the requirements enter the inner cylinder first for dry and preheat treatment, and then enter the outer cylinder for carbonization treatment. Pyrolysis and discharge – the main body of the biomass pyrolysisPyrolysis and discharge make up the primary part of the biomass pyrolysis process.

After about twenty minutes of being fed, the organism begins to produce combustible gas, and the gas in question is one that can catch fire. After going through the processes of cleaning, desulfurization, and dust removal that are carried out in the cyclone dust removal system, the mixture is then sent to the condenser to be cooled and concentrated. The wood vinegar and the tar are able to be separated from one another as a result of this process. The induced draft fan pushes the remaining gas into the main body's external combustion chamber, where it is ignited and heated up. This chamber is directed to it by the main body. This is the location where the gas is put to use. Following this step, the fan directs the flow of hot air that has been generated by the combustion chamber into the main combustion chamber, where it continues to heat the body. This step concludes the heating process. This is due to the fact that the primary combustion chamber is significantly larger than the combustion chamber that is responsible for producing heat.

Reuse of hot flue gas: a portion of the waste heat that is generated by the flue gas can be used to heat the dryer, and the remaining portion of the flue gas is discharged after being treated by the dust removal system and the flue gas purification equipment. This is referred to as the reuse of hot flue gas.

Continuous biomass pyrolysis machines that use U-type screw feeder systems have a number of advantages, some of which are frequency conversion speed regulation, uniform feeding, good sealing, absence of dust, open design, and ease of maintenance. Other advantages include the ability to control the rate of pyrolysis.

The pyrolysis arbonization cylinder has a structure that is made up of two layers: the innermost layer is the one that is pre-dried, and the outermost layer is the one that is carbonized. Stainless steel type 304, which is resistant to rust and high temperatures, is used in the construction of every point of contact that comes into contact with materials. This material is utilized in every contact point that is open to the elements or other substances.

The device uses an inner cylinder transmission mode, and its gear ring and roller ring both have increased thickness so that the device can carry out its functions in a manner that is both smooth and free of potential danger.

A room can be heated in a number of different ways, some of which include making use of diesel oil, natural gas, or liquefied petroleum gas, amongst a great deal of other potential options.

Good thermal insulation, such as high-aluminum refractory castables and ceramic fiber insulation cotton, is used in circumstances in which it is necessary to withstand high temperatures and to minimize the amount of heat that is lost to the greatest extent possible. Examples of such circumstances include ceramic fiber insulation cotton.

PLC control is an advanced automation technology that can be implemented using either the Siemens PLC S7-1500 controller or Modbus control. Both of these options are available to users. There is availability for both of these control systems.

menu

menu

Menu